120 products

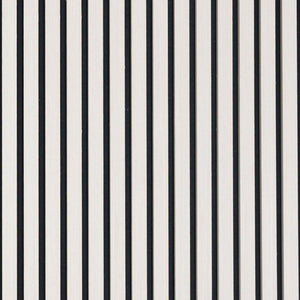

Beachfront Oak

Acoustic Slat Panels

Beachfront Oak

Acoustic Slat Panels

Length: 94.5" or 120"

Width: 23.8"

From $12.99 $11.04 sq ft